Thursday 31st March 2022

Highlights

Total Resource1,2

High Grade Resource1,2 (Reported +0.6% CuEq)

|

Hot Chili’s Managing Director Christian Easterday said:

“I would like to thank our entire team who have delivered this very strong result on-time and within guidance – elevating Costa Fuego’s position amongst the largest undeveloped copper projects in the world.

The world is hungry for advanced, low-risk, senior copper developments with near-term production potential. Copper prices are driving higher and new meaningful copper supply is fast becoming a mirage.

Hot Chili is well positioned to deliver into this forecast supply gap and contribute to the decarbonisation super cycle, particularly due to Costa Fuego’s lower economic hurdle resulting from its low elevation location and proximity to existing infrastructure; including abundant grid power with high renewables contributions.

We are fully funded for 18 months and on-track to deliver our next resource upgrade and PFS later this year as we transform Costa Fuego into one of the world’s next material copper mines.”

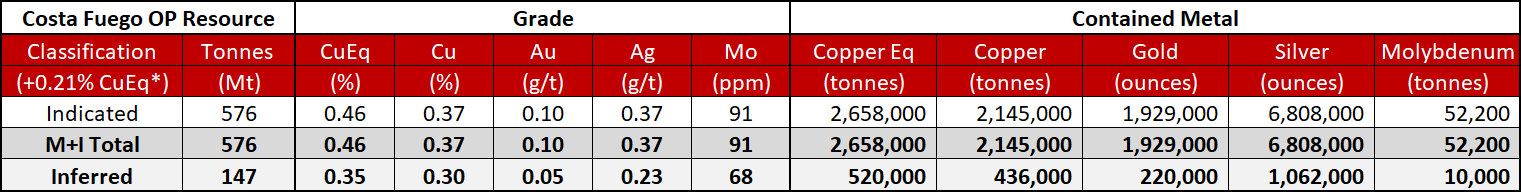

1 Reported on a 100% Basis – combining Mineral Resource estimates for the Cortadera, Productora and San Antonio deposits. Figures are rounded, reported to appropriate significant figures, and reported in accordance with CIM and NI 43-101. Metal rounded to nearest thousand, or if less, to the nearest hundred. Total Resource reported at +0.21% CuEq for open pit and +0.30% CuEq for underground

2 Copper Equivalent (CuEq) reported for the resource were calculated using the following formula: CuEq% = ((Cu% × Cu price 1% per tonne × Cu_recovery)+(Mo ppm × Mo price per g/t × Mo_recovery)+(Au ppm × Au price per g/t × Au_recovery)+ (Ag ppm × Ag price per g/t × Ag_recovery)) / (Cu price 1% per tonne). The Metal Prices applied in the calculation were: Cu=3.00 USD/lb, Au=1,700 USD/oz, Mo=14 USD/lb, and Ag=20 USD/oz. For Cortadera and San Antonio (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=56%, Mo=82%, and Ag=37%. For Productora (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=43% and Mo=42%. For Costa Fuego (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=51%, Mo=67% and Ag=23%.

Hot Chili Limited (ASX: HCH) (TSXV:HCH) (OTCQB: HHLKF) (“Hot Chili” or “Company”) is pleased to announce a major resource upgrade for its coastal range, Costa Fuego copper-gold project in Chile.

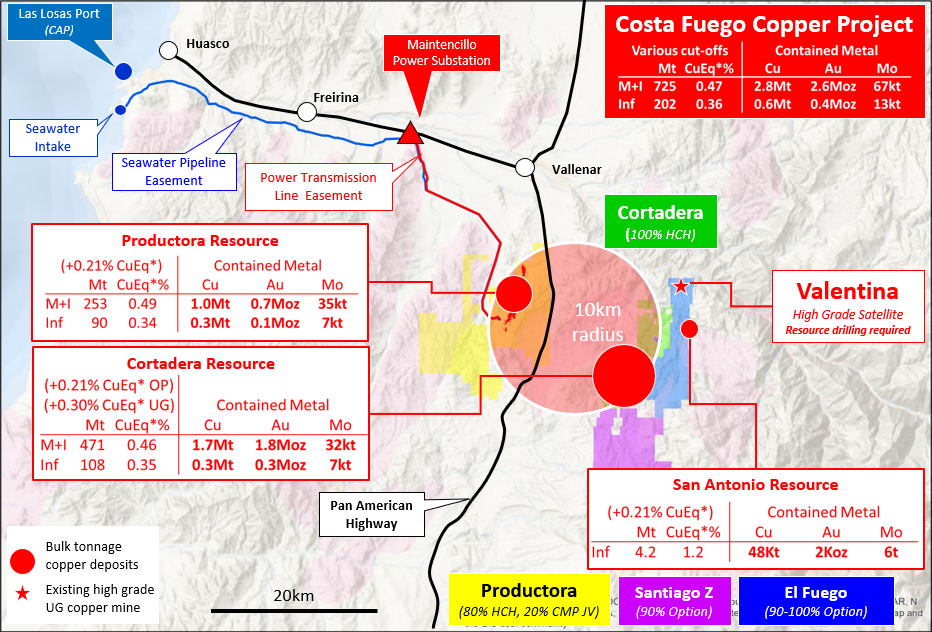

Costa Fuego comprises the Cortadera, Productora and San Antonio deposits, all of which have updated Mineral Resource Estimates (“MRE” or “resource”) and lie proximal to one another at low-altitude elevations (800m to 1,000m), 600km north of Santiago.

The resource upgrade follows 18 months of material investment, including completion of 52,000 metres of additional resource drilling at Cortadera, purchase of 100% of the Cortadera copper-gold porphyry discovery and execution of an offtake agreement with Glencore for future concentrate production (60% for the first 8 years).

The Cortadera MRE has delivered the majority of resource growth for Costa Fuego. Cortadera is defined by over 92,000m of drilling and contains an Indicated resource of 471Mt grading 0.46% CuEq (previously 183Mt grading 0.49% CuEq) and an Inferred resource of 108Mt grading 0.35% CuEq (previously 267Mt grading 0.44% CuEq).

Cortadera’s Indicated resource has grown by 134% and is now able to be studied for conversion into ore reserves in the Company’s Pre-Feasibility Study (PFS), forecast for Q3, 2022.

The Productora MRE has been re-estimated following review of the 2016 MRE, completion of underground mine development and exploration drilling in 2021. The review and subsequent resource re-estimation has resulted in a material increase in high grade Indicated resources reported above 0.6% CuEq. High grade open pit resources from Productora are a key focus for the combined PFS and are expected to feature prominently in the early mine schedule for Costa Fuego.

A maiden San Antonio MRE has also been added to the Costa Fuego Hub. San Antonio was historically exploited by small-scale underground mining of high grade copper. The maiden resource estimate utilised an underground drone survey (increasing the spatial confidence of historic mining activities) and 4,922 metres of drilling undertaken by Hot Chili in 2018.

The Company is encouraged by the initial Inferred resource of 4.2Mt grading 1.2% CuEq. The high grade, shallow nature of San Antonio provides an additional open pittable deposit for Costa Fuego’s potential early mine schedule. Further resource upgrade drilling is planned at San Antonio and the nearby Valentina high grade deposit in the coming months.

Figure 1 Location of Cortadera, Productora and San Antonio in relation to coastal range infrastructure of Hot Chili’s combined Costa Fuego copper-gold project, located 600km north of Santiago in Chile

1 Reported on a 100% Basis – combining Mineral Resource estimates for the Cortadera, Productora and San Antonio deposits. Figures are rounded, reported to appropriate significant figures, and reported in accordance with CIM and NI 43-101. Metal rounded to nearest thousand, or if less, to the nearest hundred. Total Resource reported at +0.21% CuEq for open pit and +0.30% CuEq for underground

2 Copper Equivalent (CuEq) reported for the resource were calculated using the following formula: CuEq% = ((Cu% × Cu price 1% per tonne × Cu_recovery)+(Mo ppm × Mo price per g/t × Mo_recovery)+(Au ppm × Au price per g/t × Au_recovery)+ (Ag ppm × Ag price per g/t × Ag_recovery)) / (Cu price 1% per tonne). The Metal Prices applied in the calculation were: Cu=3.00 USD/lb, Au=1,700 USD/oz, Mo=14 USD/lb, and Ag=20 USD/oz. For Cortadera and San Antonio (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=56%, Mo=82%, and Ag=37%. For Productora (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=43% and Mo=42%. For Costa Fuego (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=51%, Mo=67% and Ag=23%.

Table 1. Costa Fuego Copper-Gold Project Mineral Resource Estimate, March 2022

1 Reported on a 100% Basis – combining Mineral Resource estimates for the Cortadera, Productora and San Antonio deposits. Figures are rounded, reported to appropriate significant figures, and reported in accordance with CIM and NI 43-101. Metal rounded to nearest thousand, or if less, to the nearest hundred. Total Resource reported at +0.21% CuEq for open pit and +0.30% CuEq for underground

2 Copper Equivalent (CuEq) reported for the resource were calculated using the following formula: CuEq% = ((Cu% × Cu price 1% per tonne × Cu_recovery)+(Mo ppm × Mo price per g/t × Mo_recovery)+(Au ppm × Au price per g/t × Au_recovery)+ (Ag ppm × Ag price per g/t × Ag_recovery)) / (Cu price 1% per tonne). The Metal Prices applied in the calculation were: Cu=3.00 USD/lb, Au=1,700 USD/oz, Mo=14 USD/lb, and Ag=20 USD/oz. For Cortadera and San Antonio (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=56%, Mo=82%, and Ag=37%. For Productora (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=43% and Mo=42%. For Costa Fuego (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=51%, Mo=67% and Ag=23%.

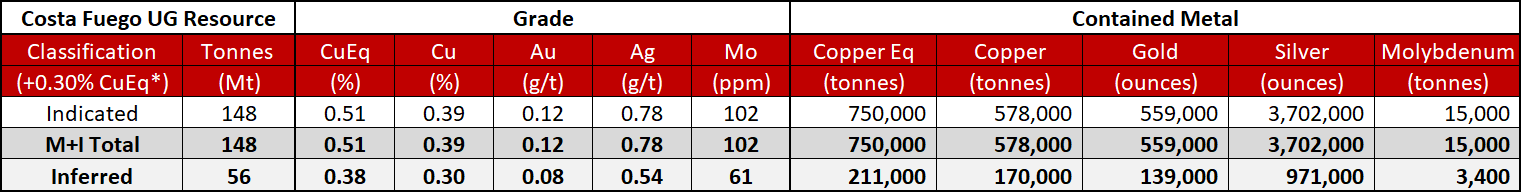

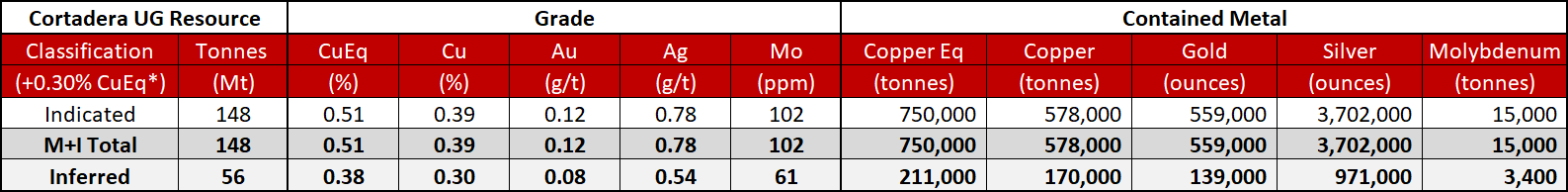

Cortadera Mineral Resource Upgrade

The Cortadera MRE upgrade follows an additional 52,000m of Diamond (DD) and Reverse Circulation (RC) drilling since the maiden resource was released in October 2020. This resulted in a 134% increase in Indicated metal tonnes in comparison to the maiden resource at the same cut-off grade.

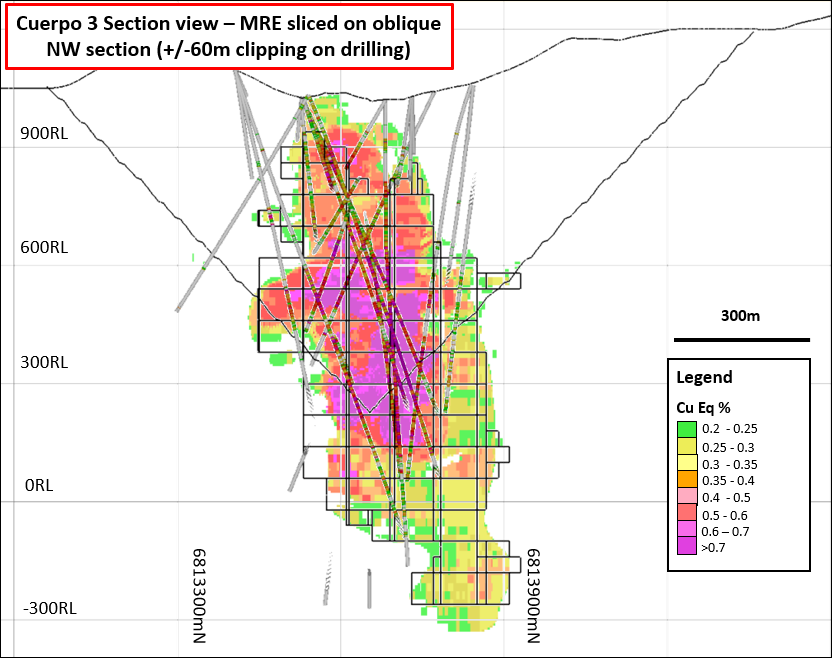

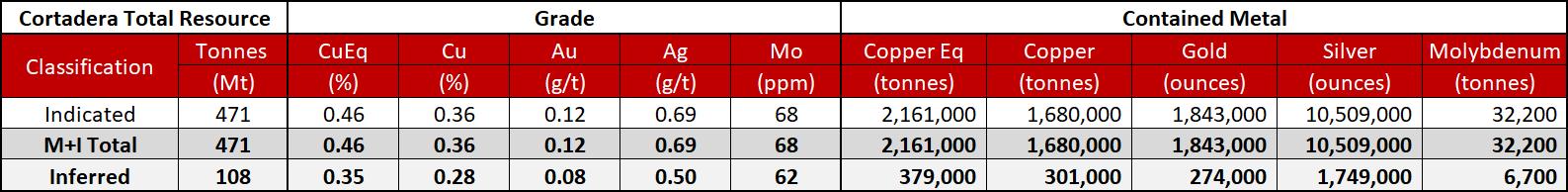

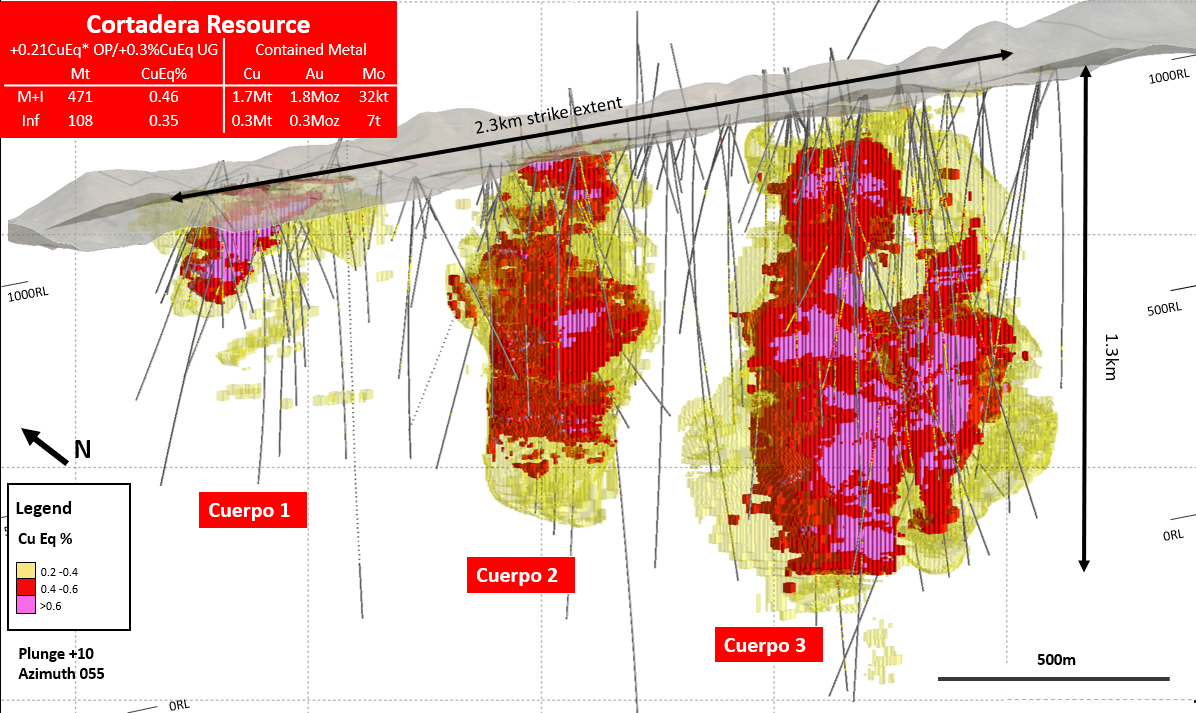

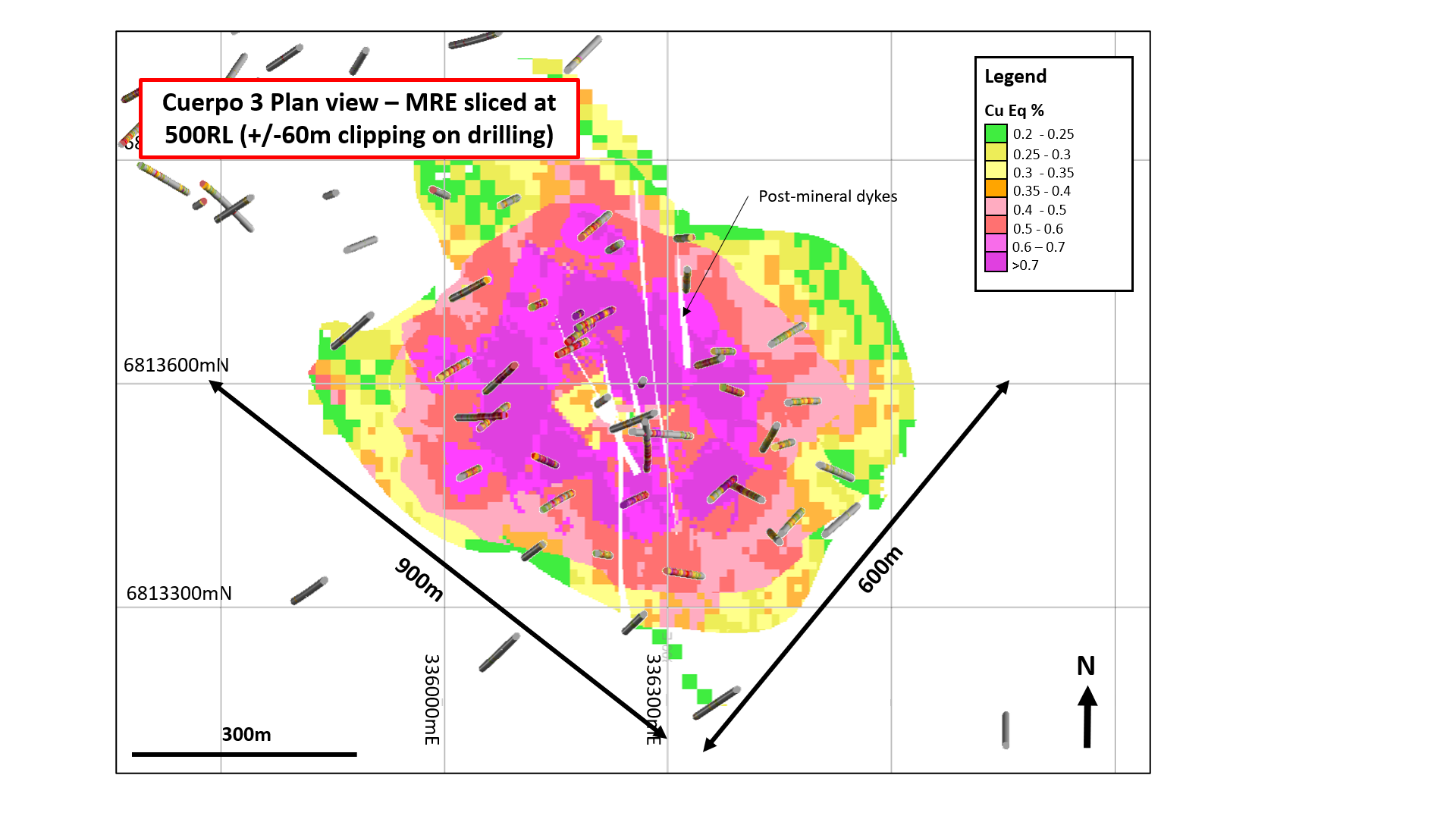

The additional drilling also enabled the delineation of high grade copper and gold domains within Cuerpo 3 (Figure 2), resulting in improved grade continuity and metal tonnes above 0.4% CuEq.

Continuity of grade and geology is controlled by the emplacement of mineralised porphyry intrusions into shallow dipping host stratigraphy. While these porphyry intrusions have a reasonably consistent pipe-like geometry, grade distribution also extends into the host stratigraphy.

Table 2 and Figures 2 and 3 below outline the upgraded Cortadera MRE.

Table 2. Cortadera Deposit Mineral Resource Estimate, March 2022

1 Reported on a 100% Basis – combining Mineral Resource estimates for the Cortadera, Productora and San Antonio deposits. Figures are rounded, reported to appropriate significant figures, and reported in accordance with CIM and NI 43-101. Metal rounded to nearest thousand, or if less, to the nearest hundred. Total Resource reported at +0.21% CuEq for open pit and +0.30% CuEq for underground

2 Copper Equivalent (CuEq) reported for the resource were calculated using the following formula: CuEq% = ((Cu% × Cu price 1% per tonne × Cu_recovery)+(Mo ppm × Mo price per g/t × Mo_recovery)+(Au ppm × Au price per g/t × Au_recovery)+ (Ag ppm × Ag price per g/t × Ag_recovery)) / (Cu price 1% per tonne). The Metal Prices applied in the calculation were: Cu=3.00 USD/lb, Au=1,700 USD/oz, Mo=14 USD/lb, and Ag=20 USD/oz. For Cortadera and San Antonio (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=56%, Mo=82%, and Ag=37%. For Productora (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=43% and Mo=42%. For Costa Fuego (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=51%, Mo=67% and Ag=23%.

Figure 2. Oblique Long Section of the Cortadera MRE displaying CuEq grade distribution in relation to drilling coverage

Mineralisation models have been generated using over 92,000m of drilling and an improved understanding of geological controls on mineralisation. Each metal has been independently optimised, resulting in improved continuity of higher and moderate grade copper, gold, silver and molybdenum within each of Cortadera’s three Cuerpos. These models correlate well with higher A + B porphyry vein percentages and other key porphyry datasets.

Extensive test work was completed to determine an optimal estimation approach and ensure the model was representative of the underlying porphyry mineralisation controls. The updated Cortadera MRE utilises a probabilistic estimation approach (Categorical Indicator Kriging (CIK)), within each mineralisation domain. This approach enabled the spatial and chronological aspects of the multiple phases of mineralisation to be better represented, resulting in higher metal tonnes above a 0.5% CuEq cut-off grade.

Figure 3. Plan view at 500m RL displaying the distribution of CuEq grade within the Cortadera MRE

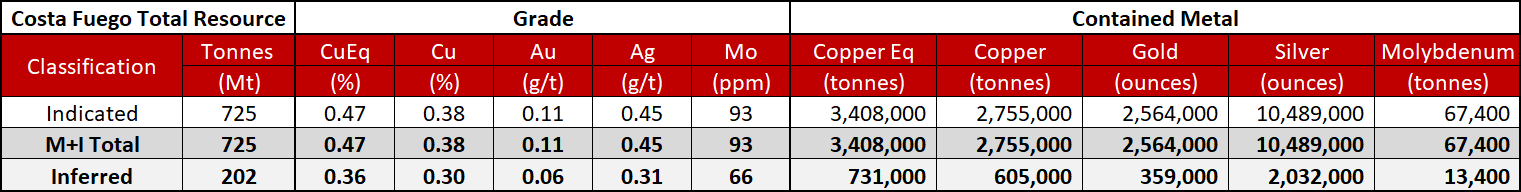

Productora Mineral Resource Update

The Productora MRE was updated following an extensive review of the 2016 resource estimate. Since 2016, copper prices have increased and underground mine development by lease miners (2020 and 2021) have reported materially higher copper grades than had been previously estimated.

The review of the 2016 MRE suggested the spatial continuity of mineralisation was not being represented sufficiently, with local-scale ductile characteristics in underground mine development not able to be accurately reflected using traditional wireframing and estimation methods. This had resulted in significant mineralised zones being excluded from the earlier resource estimation within the breccia-hosted copper deposit.

Extensive drilling and data collection by Hot Chili at Productora between 2010 and 2017 have allowed a comprehensive review of various mineralisation styles and structural complexities present within the host tourmaline breccia unit. The review determined that probabilistic techniques (CIK) were most suitable for resource estimation following analysis of all available geological, structural, alteration, assay (33 element ICP-OES analysis), geometallurgical and geotechnical information.

Using the same dataset as the 2016 MRE, the CIK approach optimised the estimations of copper, gold, molybdenum, cobalt, iron, aluminium, potassium and sulphur at Productora. Exploration drilling completed in early 2022 on the edges of the Productora resource tested the updated model, with results suggesting the new estimation approach was suitably predictive.

The updated Productora MRE is considered to be more robust than the earlier 2016 MRE and has resulted in an increase in high grade (+0.6% CuEq) Indicated material, as well as improved spatial continuity of mineralisation.

High grade open pit resources from Productora are a key focus for the combined PFS and are expected to feature prominently in the early mine schedule for Costa Fuego.

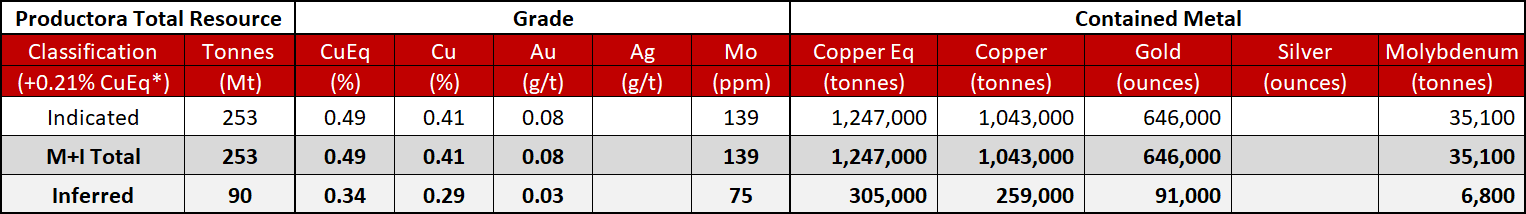

Table 3 and Figures 4 and 5 below outline the upgraded Cortadera MRE.

Table 3. Productora Deposit Mineral Resource Estimate, March 2022

1 Reported on a 100% Basis – combining Mineral Resource estimates for the Cortadera, Productora and San Antonio deposits. Figures are rounded, reported to appropriate significant figures, and reported in accordance with CIM and NI 43-101. Metal rounded to nearest thousand, or if less, to the nearest hundred. Total Resource reported at +0.21% CuEq for open pit.

2 Copper Equivalent (CuEq) reported for the resource were calculated using the following formula: CuEq% = ((Cu% × Cu price 1% per tonne × Cu_recovery)+(Mo ppm × Mo price per g/t × Mo_recovery)+(Au ppm × Au price per g/t × Au_recovery)+ (Ag ppm × Ag price per g/t × Ag_recovery)) / (Cu price 1% per tonne). The Metal Prices applied in the calculation were: Cu=3.00 USD/lb, Au=1,700 USD/oz, Mo=14 USD/lb, and Ag=20 USD/oz. For Cortadera and San Antonio (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=56%, Mo=82%, and Ag=37%. For Productora (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=43% and Mo=42%. For Costa Fuego (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=51%, Mo=67% and Ag=23%.

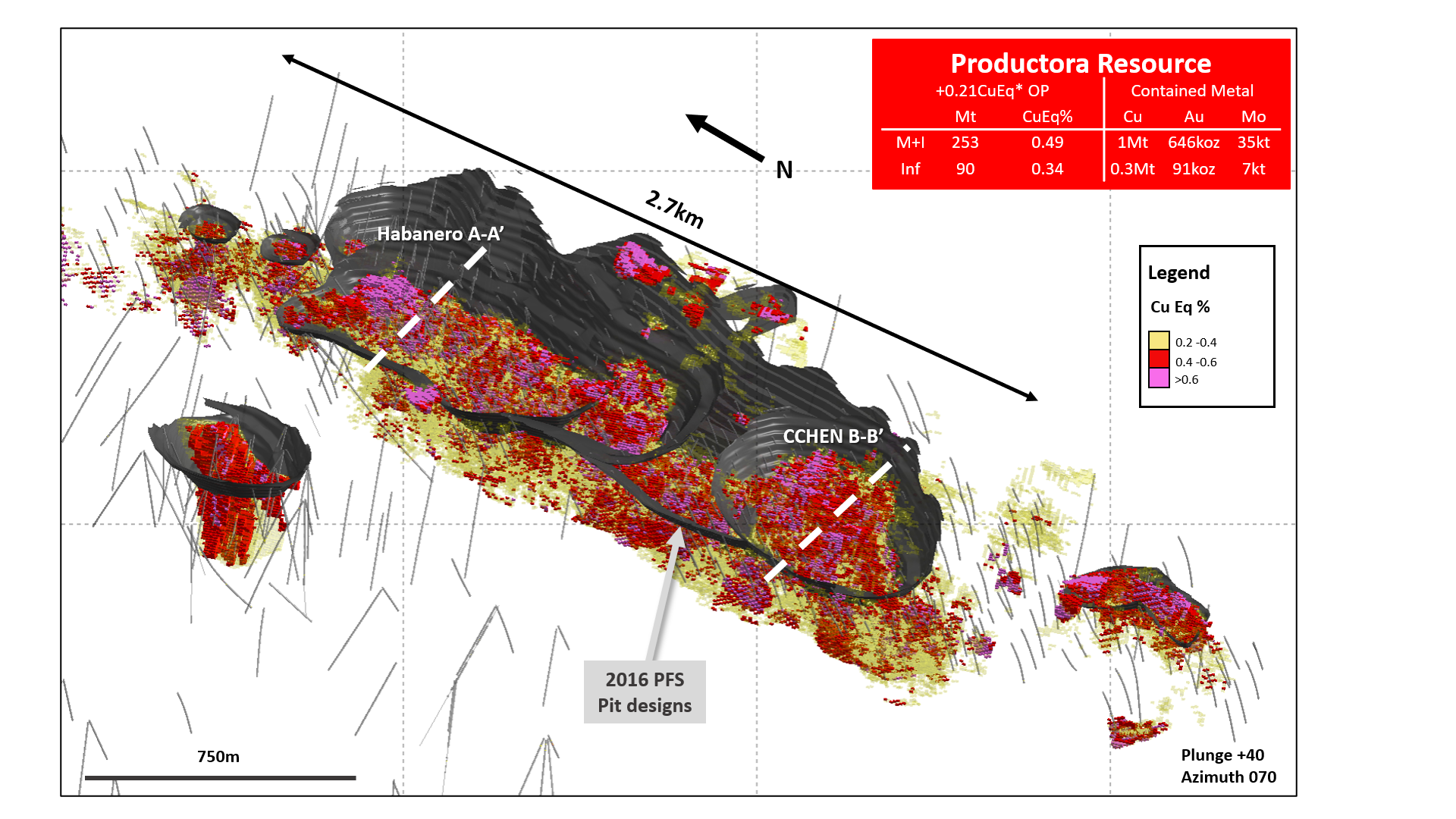

Figure 4. Oblique view of the Productora MRE in relation to drill coverage and 2016 PFS pit design

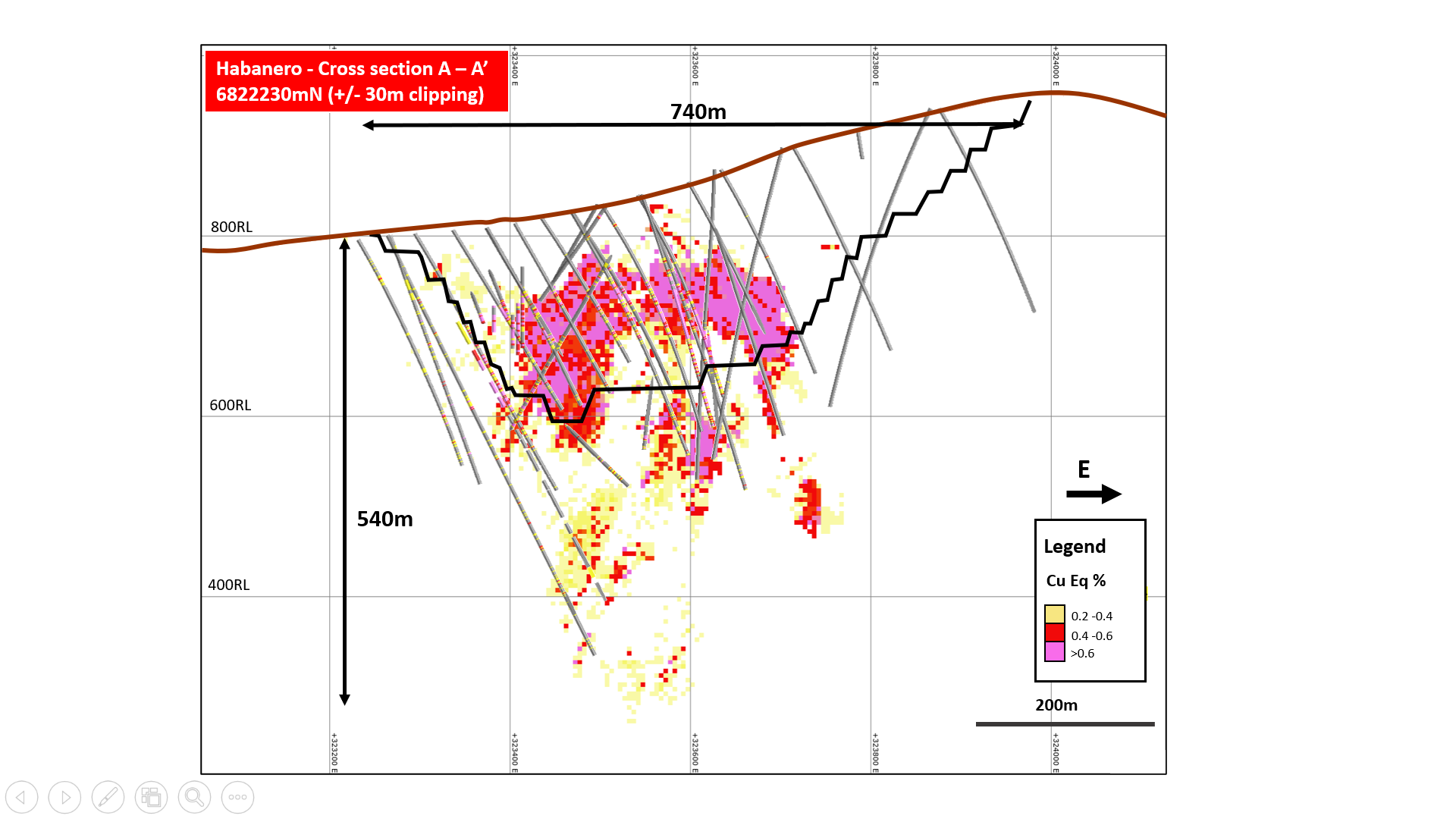

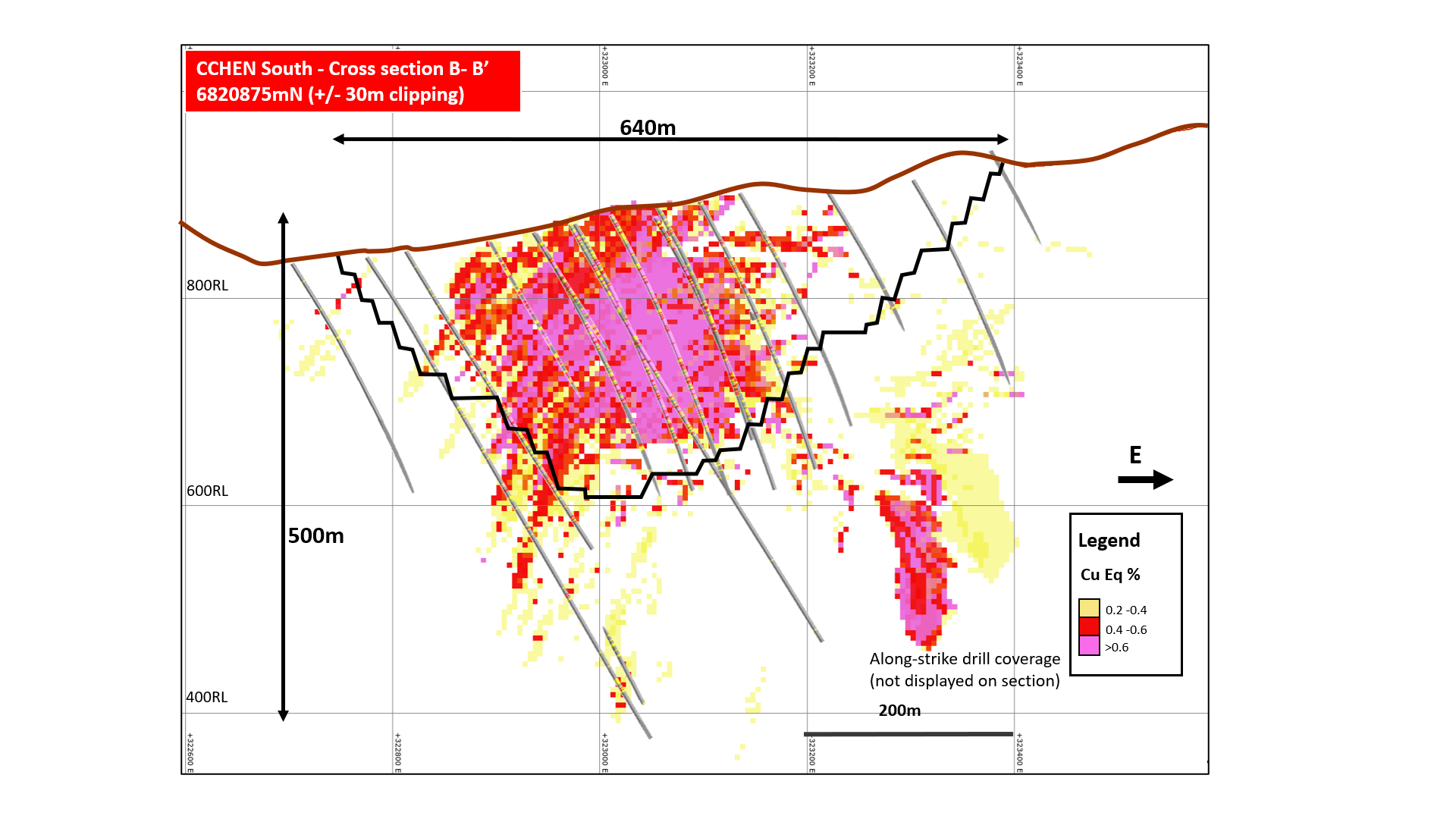

Figure 5. Two Cross-sections across the Productora MRE in relation to drilling and 2016 PFS pit design

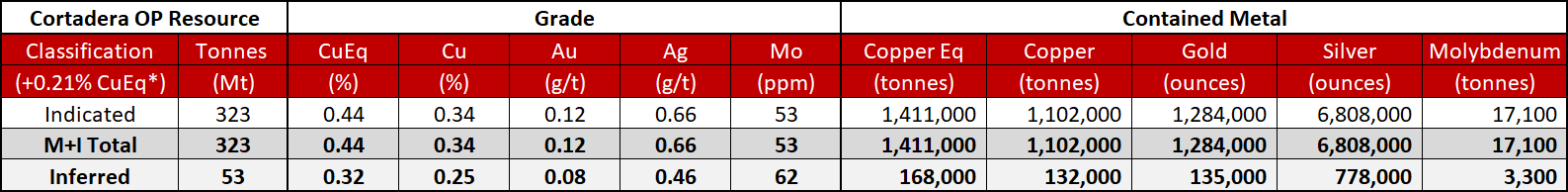

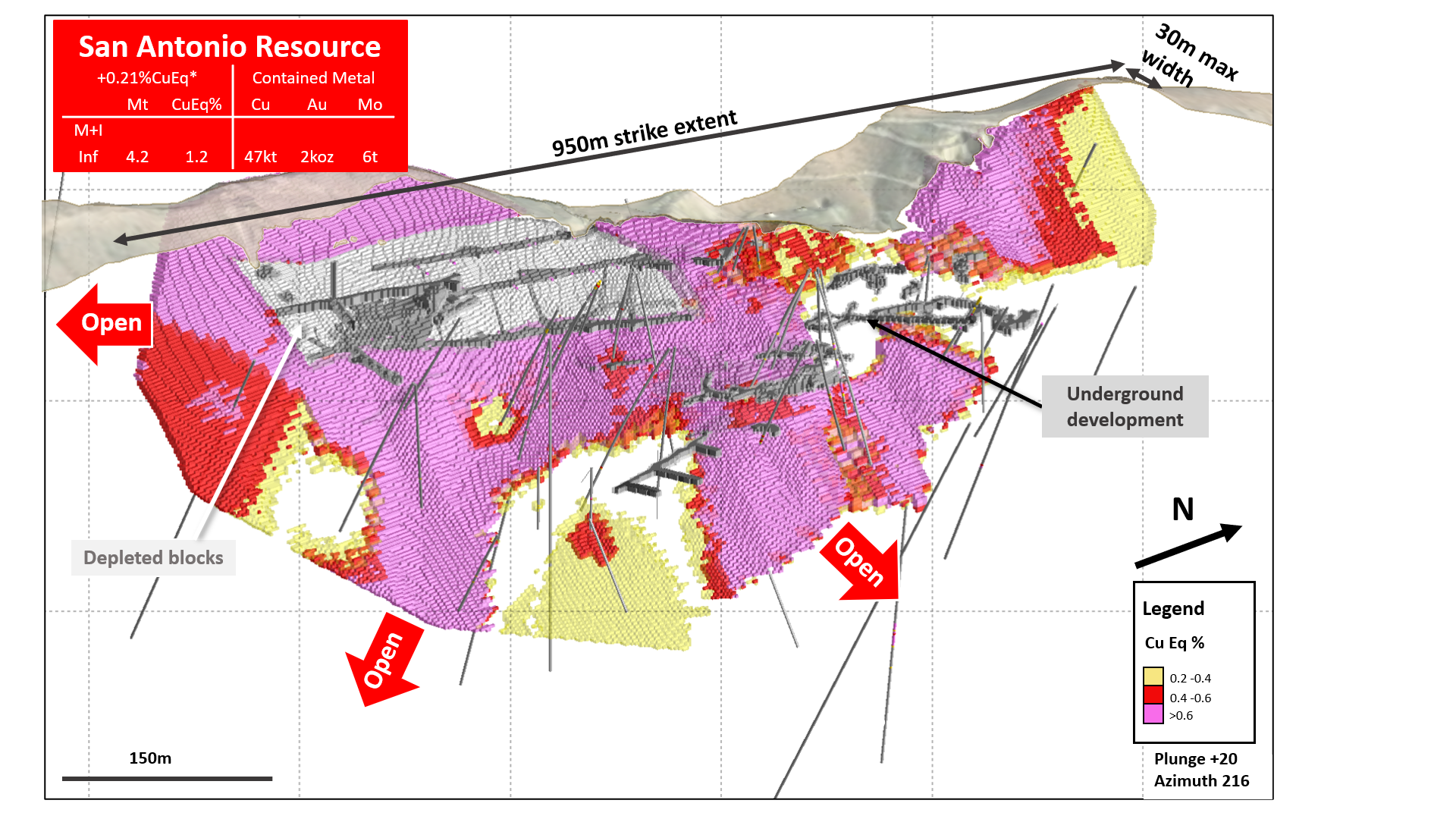

Maiden Mineral Resource for San Antonio

Hot Chili is pleased to announce a maiden MRE for the San Antonio copper deposit. Hot Chili completed a drone survey of the shallowly developed historic underground mine in 2021. This enabled increased spatial confidence of the historic mining activities at San Antonio and the ability to complete an initial Inferred resource estimate.

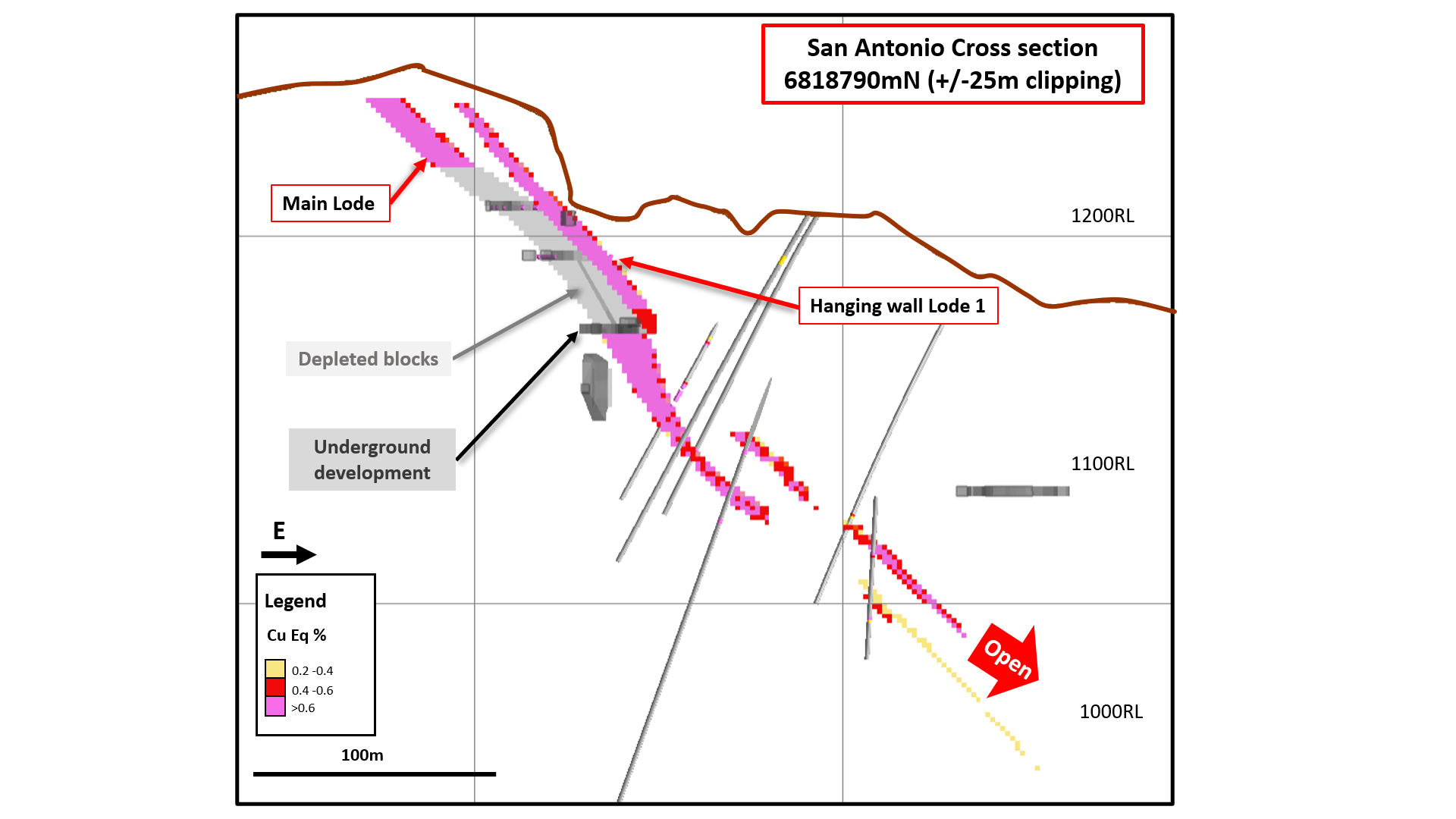

Void models previously established from historical documentation were subsequently updated, including revisions to rotation and grid transformations. The underground survey supported the Company’s geological interpretation of multiple sub parallel lodes at San Antonio.

In 2018, Hot Chili completed 4,922m of first-pass RC drilling at San Antonio, confirming significant extensions to the high grade underground mine. Hot Chili’s drilling also validated historical underground drilling and channel sampling results. Importantly, the average grade estimated within the void model shows strong alignment to historical and lease mining production reports.

Copper mineralisation at San Antonio is fault-hosted and dips moderately towards the east within a sequence of volcanic-sedimentary units that were intruded by a series of diorite and andesite dykes. High grade copper is related to chalcopyrite and bornite mineralisation in association with strong epidote alteration.

San Antonio is an important addition to the Costa Fuego resource inventory, representing the first high grade, satellite deposit outside of Cortadera and Productora. Further drilling is planned to upgrade San Antonio to Indicated classification this year.

Resource drilling is also planned this year at the proximal Valentina high grade underground mine to follow up several significant drilling intersections recorded by Hot Chili in 2018. Initial results recorded 12m grading 1.5% copper from 28m down-hole depth (including 6m grading 2.7% copper) in drill hole VAP0001 and 8m grading 2.0% copper from 124m down-hole depth (including 2m grading 4.8% copper) in drill hole VAP0003 (see ASX announcement dated 5th September 2018).

San Antonio and Valentina are an exciting addition and will feature in a planned PFS resource upgrade later this year. Both deposits are expected to provide high-grade open pit deposit for Costa Fuego’s early mine schedule.

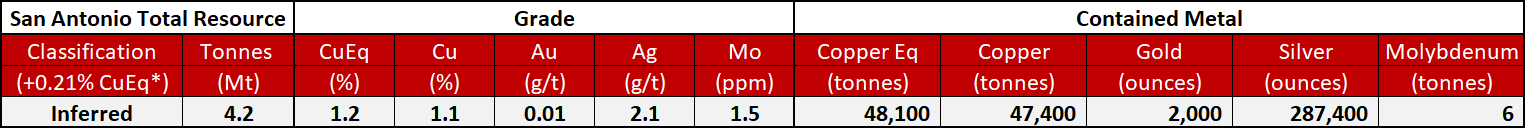

Table 4 and Figures 6 and 7 below outline the maiden San Antonio MRE.

Table 4. San Antonio Deposit Mineral Resource Estimate, March 2022

1 Reported on a 100% Basis – combining Mineral Resource estimates for the Cortadera, Productora and San Antonio deposits. Figures are rounded, reported to appropriate significant figures, and reported in accordance with CIM and NI 43-101. Metal rounded to nearest thousand, or if less, to the nearest hundred. Total Resource reported at +0.21% CuEq for open pit

2 Copper Equivalent (CuEq) reported for the resource were calculated using the following formula: CuEq% = ((Cu% × Cu price 1% per tonne × Cu_recovery)+(Mo ppm × Mo price per g/t × Mo_recovery)+(Au ppm × Au price per g/t × Au_recovery)+ (Ag ppm × Ag price per g/t × Ag_recovery)) / (Cu price 1% per tonne). The Metal Prices applied in the calculation were: Cu=3.00 USD/lb, Au=1,700 USD/oz, Mo=14 USD/lb, and Ag=20 USD/oz. For Cortadera and San Antonio (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=56%, Mo=82%, and Ag=37%. For Productora (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=43% and Mo=42%. For Costa Fuego (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=51%, Mo=67% and Ag=23%.

Figure 6. Oblique view of the San Antonio MRE in relation to drilling, underground voids and mine development

Figure 7. Cross Section across the centre of the San Antonio MRE displaying drilling and underground mine development

This announcement is authorised by the Board of Directors for release to ASX and TSXV.

For more information please contact:

|

Christian Easterday Managing Director – Hot Chili |

Tel: +61 8 9315 9009 Email: admin@hotchili.net.au |

|

|

Penelope Beattie Company Secretary – Hot Chili |

Tel: +61 8 9315 9009 Email: admin@hotchili.net.au |

|

|

ASX Investor Investor & Public Relations (Australia) |

Email: eliza@asxinvestor.com.au |

|

|

Harbor Access Investor & Public Relations (Canada) |

Email: Graham.Farrell@harboraccess.com Email: Jonathan.Paterson@harboraccess.com |

or visit Hot Chili’s website at www.hotchili.net.au

Qualifying Statements

Competent Person’s Statement- Exploration Results

Exploration information in this Announcement is based upon work compiled by Mr Christian Easterday, the Managing Director and a full-time employee of Hot Chili Limited whom is a Member of the Australasian Institute of Geoscientists (AIG). Mr Easterday has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a ‘Competent Person’ as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’ (JORC Code). Mr Easterday consents to the inclusion in the report of the matters based on their information in the form and context in which it appears.

Competent Person’s Statement- Costa Fuego Mineral Resources

The information in this report that relates to Mineral Resources for Cortadera, Productora and San Antonio which constitute the combined Costa Fuego Project is based on information compiled by Ms Elizabeth Haren, a Competent Person who is a Member and Chartered Professional of The Australasian Institute of Mining and Metallurgy and a Member of the Australian Institute of Geoscientists. Ms Haren is a full-time employee of Haren Consulting Pty Ltd and an independent consultant to Hot Chili. Ms Haren has sufficient experience, which is relevant to the style of mineralisation and types of deposits under consideration and to the activities undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code of Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Ms Haren consents to the inclusion in the report of the matters based on her information in the form and context in which it appears. For further information on the Costa Fuego Project, refer to the technical report titled “Resource Report for the Costa Fuego Technical Report”, dated December 13, 2021, which is available for review under Hot Chili’s profile at www.sedar.com.

Reporting of Copper Equivalent

Copper Equivalent (CuEq) reported for the resource were calculated using the following formula: CuEq% = ((Cu% × Cu price 1% per tonne × Cu_recovery)+(Mo ppm × Mo price per g/t × Mo_recovery)+(Au ppm × Au price per g/t × Au_recovery)+ (Ag ppm × Ag price per g/t × Ag_recovery)) / (Cu price 1% per tonne). The Metal Prices applied in the calculation were: Cu=3.00 USD/lb, Au=1,700 USD/oz, Mo=14 USD/lb, and Ag=20 USD/oz. For Cortadera and San Antonio (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=56%, Mo=82%, and Ag=37%. For Productora (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=43% and Mo=42%. For Costa Fuego (Inferred + Indicated), the average Metallurgical Recoveries were: Cu=83%, Au=51%, Mo=67% and Ag=23%.

Forward Looking Statements

This Announcement is provided on the basis that neither the Company nor its representatives make any warranty (express or implied) as to the accuracy, reliability, relevance or completeness of the material contained in the Announcement and nothing contained in the Announcement is, or may be relied upon as a promise, representation or warranty, whether as to the past or the future. The Company hereby excludes all warranties that can be excluded by law. The Announcement contains material which is predictive in nature and may be affected by inaccurate assumptions or by known and unknown risks and uncertainties and may differ materially from results ultimately achieved.

The Announcement contains “forward-looking statements”. All statements other than those of historical facts included in the Announcement are forward-looking statements including estimates of Mineral Resources. However, forward-looking statements are subject to risks, uncertainties and other factors, which could cause actual results to differ materially from future results expressed, projected or implied by such forward-looking statements. Such risks include, but are not limited to, copper, gold and other metals price volatility, currency fluctuations, increased production costs and variances in ore grade recovery rates from those assumed in mining plans, as well as political and operational risks and governmental regulation and judicial outcomes. The Company does not undertake any obligation to release publicly any revisions to any “forward-looking statement” to reflect events or circumstances after the date of the Announcement, or to reflect the occurrence of unanticipated events, except as may be required under applicable securities laws. All persons should consider seeking appropriate professional advice in reviewing the Announcement and all other information with respect to the Company and evaluating the business, financial performance and operations of the Company. Neither the provision of the Announcement nor any information contained in the Announcement or subsequently communicated to any person in connection with the Announcement is, or should be taken as, constituting the giving of investment advice to any person

Disclaimer

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release.

Appendix 1. JORC Code Table 1 for Costa Fuego

The following table provides a summary of important assessment and reporting criteria used for Cortadera, Productora and San Antonio which constitute the combined Costa Fuego Project and for the reporting of Mineral Resource and Ore Reserves in accordance with the Table 1 checklist in the Australasian Code for the Reporting of Exploration Results, Minerals Resources and Ore Reserves (The JORC Code, 2012 Edition).

The Cortadera, Productora and San Antonio MRE’s are reported to the standard of the Canadian National Instrument 43-101 “Standards of Disclosure for Mineral Projects”, and as such have been completed by a Qualified Person (QP). A QP under NI43-101 guidelines is interchangeable with a Competent Person (CP) under the JORC Code and has been referred to as such below.

The follow list provides the names and the sections for Competent Person responsibilities for Section 1, 2 and 3:

Christian Easterday (MAIG) (Hot Chili Limited) and Elizabeth Haren (MAusIMM and MAIG) (Haren Consulting Pty Ltd)

Section 1 Sampling Techniques and Data – Cortadera: Christian Easterday

Section 2 Reporting of Exploration Results – Cortadera: Christian Easterday

Section 3 Estimation and Reporting of Mineral Resources – Cortadera: Elizabeth Haren

Section 1 Sampling Techniques and Data – Productora: Christian Easterday

Section 2 Reporting of Exploration Results – Productora: Christian Easterday

Section 3 Estimation and Reporting of Mineral Resources – Productora: Elizabeth Haren

Section 1 Sampling Techniques and Data – San Antonio: Christian Easterday

Section 2 Reporting of Exploration Results – San Antonio: Christian Easterday

Section 3 Estimation and Reporting of Mineral Resources – San Antonio: Elizabeth Haren

Appendix 1. JORC Code Table 1 for Cortadera

The following table provides a summary of important assessment and reporting criteria used for the reporting of Mineral Resource and Ore Reserves in accordance with the Table 1 checklist in the Australasian Code for the Reporting of Exploration Results, Minerals Resources and Ore Reserves (The JORC Code, 2012 Edition).

The Cortadera MRE will be reported to the standard of the Canadian National Instrument 43-101 “Standards of Disclosure for Mineral Projects”, and as such has b/een completed by a Qualified Person (QP). A QP under NI43-101 guidelines is interchangeable with a Competent Person (CP) under the JORC Code and has been referred to as such below.

The follow list provides the names and the sections for Competent Person responsibilities:

Section 1, 2 and 3: C. Easterday – MAIG (Hot Chili Limited), E. Haren (MAusIMM and MAIG) (Haren Consulting Pty Ltd)

Section 1 Sampling Techniques and Data

Section 2 Reporting of Exploration Results

Section 3 Estimation and Reporting of Mineral Resources

|

Criteria |

JORC Code explanation |

Commentary |

||||||||||||||||||||||||

|

Database integrity |

|

All drilling data is stored in the HCH exploration acQuire™ drillhole database. The system is backed up daily to a server based in Perth. All data is transferred electronically and is checked prior to upload to the database. In-built validation tools are used in the acQuire™ database and data loggers are used to minimise data entry errors, flag potential errors, and validate against internal library codes. Data that is found to be in error is investigated and corrected where possible. If the data cannot be resolved or corrected, it was removed from the data set used for Mineral Resource modelling and estimation. Routine checks of raw assay data against the database have been implemented. Drillhole collars are visually validated and compared to planned locations. Downhole trends and sectional trends are validated, and outliers checked. Statistical analysis of assay results by geology domains are checked for trends and outliers. The drillhole database used for the MRE has been validated by several methods including checking of QA/QC data, extreme outlier values, zero values, negative values, possible miscoded data based on geological domaining and assay values, sample overlaps, and inconsistencies in length of drillhole surveyed, length of drillhole logged and sampled, and sample size at laboratory. |

||||||||||||||||||||||||

|

Site visits |

|

A site visit was not undertaken by the Competent Person (Ms Elizabeth Haren) due to the ongoing Covid-19 Pandemic, however Ms Haren is familiar with the deposit having completed the Maiden Resource in 2020. |

||||||||||||||||||||||||

|

Mineralisation at Cortadera is centred on three multi-phase tonalitic intrusions (Cuerpo 1, 2 and 3), each capped by a copper oxide horizon. There is sufficient drilling into each of the intrusions to enable confident interpretation of the mineralisation. Most of the contained metal is in the core of the mineralised intrusions, where the highest density of drillholes occur. Continuity of grade and geology is controlled by the emplacement of the mineralised intrusions into the gently south-easterly dipping host stratigraphic units. While these intrusions have a reasonably consistent pipe-like geometry, grade distribution is complex and extends into the host stratigraphic units. Statistical analysis suggests that the copper grade decreases outwards from the porphyry core and that gradational boundary conditions exist between different rock units. For these reasons, while the distribution of rock types has guided ore interpretations, it has not been used to constrain the mineralised domains. Mineralisation domains were constructed independently for each estimated element using cut-off grades guided by grade distribution. While mineralisation domains do not always directly correlate with geological domains, each mineralisation domain is reconciled against the geological interpretation to ensure all observations (i.e., geological logging, surface mapping and knowledge of regional and local structural trends) are given proper consideration. Copper mineralisation domains are created using a set of geological conditions (as described below) on validated drillholes composited to 10 m intervals.

Mineralisation domains for gold, silver, molybdenum and cobalt were created using grade interpolants on validated drillholes composited to 10 m. Additional points and/or strings may be used to guide the interpretation in areas of lower data density or complex geology. The presence of a calcium-rich alteration front is considered to exert a significant geological control on mineralisation and appears to correlate well with zones of higher A- and B-type quartz vein abundances and copper grades that extend outward from the mineralised porphyry intrusions. This geometrical relationship is consistent with the addition of potassium and sodium to the porphyry core (along with Cu, Au, Mo, Ag and other metals), where calcium has been depleted. The calcium has been remobilised and driven outwards along permeable pathways that developed in zones of higher fracture- and vein-abundance and within adjacent competent hornfels and permissive stratigraphic units. The geometry of the mineralisation domains for copper, gold and silver estimates account for this, with mineralisation volumes appearing to ‘mushroom’ along the gently south-easterly dipping front that broadly conforms to the orientation and dip-direction of the host stratigraphic units. A 0.10% copper equivalent (CuEq) interpolant defines the outer extent of the mineralisation. The CuEq equation considers assayed copper, gold, silver and molybdenum and provides volume constraint for the low-grade estimate for each element. All mineralisation domains were created in Leapfrog Geo by HCH geologists. Wireframes defining oxide, transitional and fresh material were created in Leapfrog software and used to apply density and element recoveries which contribute to the CuEq variable. Limonite rich domains were observed during subsequent drilling since the Maiden MRE and were modelled in Leapfrog software using a combination of logging (copper oxide mineralisation and extent of iron-oxide mineral development) and copper grade cut offs. These domains are wholly contained within the Oxide and Transition surfaces and are considered a Supergene enrichment zone, particularly at Cuerpo 2. |

|||||||||||||||||||||||||

|

Dimensions |

|

Mineralisation is centred on three intrusions (Cuerpo 1, 2 and 3), which together extend approximately 2.3km along a west-north-westerly strike-direction. Dimensions across strike and down dip (inclusive of high-grade and medium grade interpolants) are: Cuerpo 1: 350m x 250m Cuerpo 2: 200m x 600m Cuerpo 3: 400m x 1050m |

||||||||||||||||||||||||

|

Estimation and modelling techniques |

|

Estimation methodology is described below for each of the elements. The copper oxides are listed separately as they comprise a distinct volume within the oxide and transitional horizons which required all elements to be estimated. For all estimates, a 2m composite was used as this represents the dominant sample length at Cortadera. Datamine software process COMPDH was used to extract variable length 2m down-hole composites. This adjusts the sample intervals where required to ensure all samples were included in the composite file (i.e., no residuals) while keeping the sample interval as close to the desired sample interval as possible. All estimates were completed into parent blocks, with sizes ranging from 10m x 10m x 10m up to 20m x 20m x 20m. Minimum cell size is 2m x 2m x 2m. Parent blocks are discretised into 4 x 4 x 4 points. The selection of search and estimation parameters was informed by kriging neighbourhood analysis which reflected the relative conditional bias which could be expected by using various configurations of block size, search size, number of samples and block discretisation based on the modelled continuity and distribution of drillhole composites. Searches were completed in three passes, with search distances approximately 2/3 of the variogram range, increasing by a factor until all blocks are filled. All statistical analysis has been completed in Snowden Supervisor Version 8.14.3.0. Grade estimation has been completed in Datamine Studio RM Version 1.10.200. —- Copper: Copper (Cu) estimates were completed independently by Cuerpo. For Cuerpo 3, three estimation domains have been used:

Within the HG domain, a CIK estimation approach has been used to account for the complex internal mineralisation within the mineralised porphyry and host rock. Cut-off grades were set at 0.2% Cu and 0.5% Cu, with the indicator estimate completed into 5m x 5m x 5m blocks to ensure reasonable granularity. Probability thresholds were selected at 0.2 (for the 0.2% cut-off) and 0.4 (for the 0.5% cut-off). The result of the indicator estimate was three sub-domains (HG_CIK, MG_CIK and LG_CIK) within the HG domain. One-way soft boundaries have been used from HG_CIK to MG_CIK and MG_CIK to LG_CIK subdomains. This approach is based on the observation that the mineralised system comprises a high-grade ‘core’ with gradational copper grade decreasing outwards to the edge of the porphyry intrusion and into wall rock. Rigorous test work has shown that the CIK approach with one-way soft boundaries is the optimal way to estimate the observed grade trends. The one-way soft boundaries are controlled using the Datamine MAXKEY approach. For the Cuerpo 3 HG domain, a maximum of 7 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 7 samples are allowed per drillhole. The LG domain comprises a mixture of sporadically mineralised porphyry and altered wall rock. The mixed grade population necessitated the use of a CIK approach to ensure neither overestimation nor grade dilution were occurring. A single cut-off grade of 0.1% Cu has been used, with the indicator estimate completed into 5m x 5m x 5m blocks to ensure reasonable granularity. A probability threshold of 0.5 was chosen, resulting in two sub-domains (HG_CIK and LG_CIK) within the LG domain. Blocks within the HG_CIK subdomain were able to select composites from the HG estimation domain. This one-way soft boundary assists in modelling the gradational grade trends observed in the mineralised system. For the Cuerpo 3 LG domain, a maximum of 4 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 4 samples are allowed per drillhole. The Waste domain comprises all remaining data out to the 0.10% CuEq interpolant. Ordinary Kriging has been used to estimate the waste domain. Blocks within the waste subdomain were able to select composites from the LG estimation domain. For the Cuerpo 3 waste domain, a maximum of 4 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 4 samples are allowed per drillhole. For Cuerpo 2, three estimation domains have been used:

Within the HG domain, a CIK estimation approach has been used to account for the complex internal mineralisation within the mineralised porphyry and host rock. A single cut-off grade of 0.17% Cu has been used, with the indicator estimate completed into 5m x 5m x 5m blocks to ensure reasonable granularity. A probability threshold of 0.4 was chosen, resulting in two sub-domains (HG_CIK and LG_CIK) within the LG domain. A one-way soft boundary has been used between the HG_CIK to LG_CIK subdomains. For the Cuerpo 2 HG domain, a maximum of 5 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 5 samples are allowed per drillhole. The LG domain comprises low-grade mineralised porphyry. Ordinary Kriging has been used to estimate the LG domain. Blocks within the LG estimation domain were able to select composites from the HG estimation domain. For the Cuerpo 2 LG domain, a maximum of 5 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 5 samples are allowed per drillhole. The Waste domain estimate was completed using the same approach as for Cuerpo 3. For Cuerpo 1, three estimation domains have been used:

Within the HG domain, a CIK estimation approach has been used to account for the complex internal mineralisation within the mineralised porphyry and host rock. A single cut-off grade of 0.3% copper has been used, with the indicator estimate completed into 5m x 5m x 5m blocks to ensure reasonable granularity. A probability threshold of 0.4 was chosen, resulting in two sub-domains (HG_CIK and LG_CIK) within the LG domain. A one-way soft boundary has been used between the HG_CIK to LG_CIK subdomains. For the Cuerpo 1 HG domain, a maximum of 5 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 5 samples are allowed per drillhole. LG domain and Waste domain estimates were completed using the same approach as for Cuerpo 2. Gold: Gold (Au) estimates were completed independently by Cuerpo. For Cuerpo 3, three estimation domains have been used:

Given the strong statistical correlation between gold and copper (R=~0.7), copper CIK subdomains and boundary conditions have been used for the gold estimate for both the HG domain and LG domain. The Waste domain comprises all remaining data out to the 0.05% CuEq interpolant. Ordinary Kriging has been used to estimate the waste domain. Blocks within the waste subdomain were able to select composites from the LG estimation domain. For the Cuerpo 3 waste domain, a maximum of 4 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 4 samples are allowed per drillhole. For Cuerpo 2, three estimation domains have been used:

Within the HG domain, a CIK estimation approach has been used to account for the complex internal mineralisation within the mineralised porphyry and host rock. A single cut-off grade of 0.10 ppm gold has been used, with the indicator estimate completed into 5m x 5m x 5m blocks to ensure reasonable granularity. A probability threshold of 0.4 was chosen, resulting in two sub-domains (HG_CIK and LG_CIK) within the LG domain. A one-way soft boundary has been used between the HG_CIK to LG_CIK subdomains. For the Cuerpo 2 HG domain, a maximum of 5 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 5 samples are allowed per drillhole. The LG domain comprises low-grade mineralised porphyry. Ordinary Kriging has been used to estimate the LG domain. Blocks within the LG estimation domain were able to select composites from the HG estimation domain. For the Cuerpo 2 LG domain, a maximum of 5 samples are used across subdomains (against a maximum sample count of 20). In addition to this, a maximum of 5 samples are allowed per drillhole. The Waste domain estimate was completed using the same approach as for Cuerpo 3. For Cuerpo 1, three estimation domains have been used:

Ordinary Kriging was used for all estimation domains in Cuerpo 1. One-way soft boundaries were used between the HG domain and LG domain and the LG domain and Waste domain. In both cases, a maximum of 5 samples were able to be selected through the soft boundary against a maximum sample count of 20. In addition to this, a maximum of 5 samples are allowed per drillhole. Silver: Silver (Ag) estimates were completed independently by Cuerpo. For Cuerpo 2 and 3, Silver is estimated into five domains:

Ordinary Kriging was used for all estimation domains in Cuerpo 2 and 3. One-way soft boundaries were used between the HG and HG_EXP domains, HG_EXP and MG domains, MG and MG_EXP domains, and MG_EXP and LG domains. In all cases, a maximum of 7 samples were able to be selected through the soft boundary against a maximum sample count of 16. In addition to this, a maximum of 7 samples are allowed per drillhole. For Cuerpo 1, Silver is estimated into three domains:

Ordinary Kriging was used for all estimation domains in Cuerpo 1. One-way soft boundaries were used between the MG and MG_EXP domains, and MG_EXP and LG domains. In both cases, a maximum of 7 samples were able to be selected through the soft boundary against a maximum sample count of 16. In addition to this, a maximum of 7 samples are allowed per drillhole. Molybdenum: Molybdenum (Mo) estimates were completed independently by Cuerpo. For all Cuerpo’s, Molybdenum is estimated into three domains:

Ordinary Kriging was used for all estimation domains. One-way soft boundaries were used between the HG and MG domains, and MG and LG domains. In all cases, a maximum of 7 samples were able to be selected through the soft boundary against a maximum sample count of 16. In addition to this, a maximum of 7 samples are allowed per drillhole. Copper Oxides: Estimation of Copper (Cu) and Gold (Au) within the copper oxide horizons used Categorical Indicator Kriging (CIK). The copper oxides were interpreted as geological domains, and so comprised mixed grade populations not suited to a conventional linear estimation approach. Cut-off grades for the indicator estimate were set at 0.35% for Cuerpo 1, 0.30% for Cuerpo 2 and 0.02%/0.09% for Cuerpo 3. The indicator estimate was completed into 1m x 1m x 1m blocks to ensure reasonable granularity. Probability thresholds used for the final estimate were 0.5 for Cuerpo 1, 0.5 for Cuerpo 2 and 0.8, 0.5 for Cuerpo 3. Downhole declustering via the Datamine process MAXKEY approach ensured that no more than 7 composites could be used for each drillhole. Silver and Molybdenum were estimated within the iron oxide using a conventional Ordinary Kriged estimate. Soluble Copper: Estimation of soluble copper within the oxide and transitional weathering domains used Ordinary Kriging. Downhole declustering via the Datamine process MAXKEY approach ensured that no more than 7 composites could be used for each drillhole. —- Comparisons to the maiden Cortadera resource (September 2020) are presented in the above presentation with section views and tabulated figures. No assumptions have been made regarding the recovery of by-products. Selective mining units have not been modelled. Correlation between elements was investigated using the 2m composites with very strong correlation between Cu and Au and Cu and Ag and moderate to strong correlation between Au and Ag. Mo showed no correlation to the other elements. The correlations between Cu, Au and Ag were reflected in the similar estimation volumes and continuity in the variogram models used for estimation. The estimates were validated using a three-stage comparison between top-cut composites and the estimated variables. The first stage involves calculating the global statistics of the composites compared to the tonnage weighted averages of estimated variables. The second stage involves comparing statistics in slices along the mineralisation and the third involves a detailed visual comparison by section to ensure the estimated variables honour the input composite data. No reconciliation data is available. |

||||||||||||||||||||||||

|

Moisture |

|

Tonnages are on a dry basis. |

||||||||||||||||||||||||

|

Cut-off parameters |

|

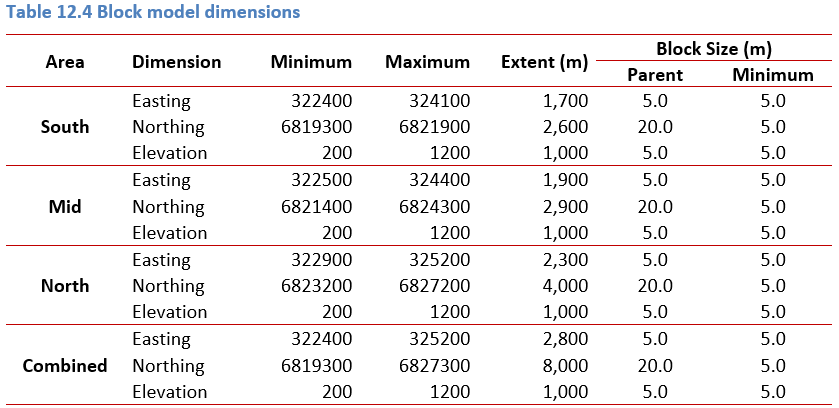

A cut-off grade of 0.21% Copper Equivalent (CuEq) was adopted for the Open Pit resource, and a 0.30% Copper Equivalent (CuEq) was adopted for the Underground Resource. Hot Chili completed a Pre-feasibility Study into the Productora Project in 2016. Productora lies approximately 14 km from Cortadera and this study identified that bulk-scale mining by open pit methods was profitable at grades lower than 0.21% CuEq. Wood benchmarked 20 block caving operations and projects globally, identifying the resource cut-off grade applied. The adopted resource cut-off grade of 0.3%CuEq for block cave mining was supported by this benchmarking. Wood also benchmarked the capital and operating costs of block caving against the throughput of each operation or planned project. This enabled a separate assessment of costs to confirm that a resource cut-off grade of 0.3% CuEq was appropriate for economic extraction by block caving methods. Cross section through Cuerpo 3 showing the Open Pit and Underground RPEEE shapes used for Cortadera reporting at 0.21% CuEq and 0.3% CuEq, respectively

|

||||||||||||||||||||||||

|

Mining factors or assumptions |

|

Near-surface ore was assumed to be mined using open-pit mining using conventional truck and shovel equipment. The economic limit of mining for the resource was established using the Lerchs-Grossman algorithm with cost inputs from the Productora Pre-feasibility Study and optimistic, long-term, metal prices, specifically USD 4.3/lb copper, USD 1,700/oz gold, USD 14/lb molybdenum, USD 20/oz silver). Material within the economic limit of open pit mining is considered to have Reasonable Prospects of Eventual Economic Extraction. Mineralisation below the open-pit limit was assumed to be mined using block caving, which was selected because it is used extensively to mine deep porphyry ore bodies of similar size. A cave void of 80mW x 80mL x >80mH was assumed to be a suitable size to initiate caving, albeit at a minimum scale. Geotechnical data is not currently sufficient to confirm caveability, or specify a minimum cave size, because resource definition work is at an early stage. The cave void shape was established using a CuEq cut-off grade of 0.30%, based on benchmark block caving costs and the optimistic, long-term, metal prices above. Cave voids included any internal dilution (without becoming uneconomic), however, while dilution was accounted for, it is not reported here because it has not been calculated with sufficient information or rigor to reliably characterise the block cave mining for the project. All material within the cave voids was considered to have Reasonable Prospects of Eventual Economic Extraction. |

||||||||||||||||||||||||

|

Metallurgical factors or assumptions |

|

Wood performed a preliminary comminution and flotation assessment on two samples of fresh sulphide material from Cortadera. A high- and low-grade sample were tested and the results support the assumption of using the conventional flotation flowsheet established for Productora to effectively recover copper, gold, molybdenum and silver from Cortadera mineralisation in payable amounts. A preliminary leach assessment of oxide material was performed, using bottle-roll acid leach tests on three samples using three pH levels. The limited testing is consistent with the leach results of the Productora Pre-feasibility Study and supports the assumption of similar recovery performance. Metallurgical test work on transitional material was not performed because there is limited material to select a sample from and the quantity of transitional material is relatively small. Transitional recovery was assumed to be the same as Productora for all elements except silver, which assumed the gold recovery value. Average recoveries for each domain are:

Copper Equivalent values reported for the resource were calculated using these metal prices: Copper 3.00 USD/lb, Molybdenum 14 USD/lb, Gold 1,700 USD/oz and Silver 20 USD/oz. The formula for calculation of copper equivalent was: CuEq = ((Cu% × Cu price 1% per tonne × Cu_recovery)+(Mo ppm × Mo price per g/t × Mo_recovery)+(Au ppm × Au price per g/t × Au_recovery)+ (Ag ppm × Ag price per g/t × Ag_recovery)) / (Cu price 1 % per tonne) Samples were assayed for multiple elements and no significant levels of concentrate impurities were identified. |

||||||||||||||||||||||||

|

Environmental factors or assumptions |

|

Waste rock disposal will be via surface landforms that will be rehabilitated at the end of the mine life. Process tailings will be stored in surface storage facilities. |

||||||||||||||||||||||||

|

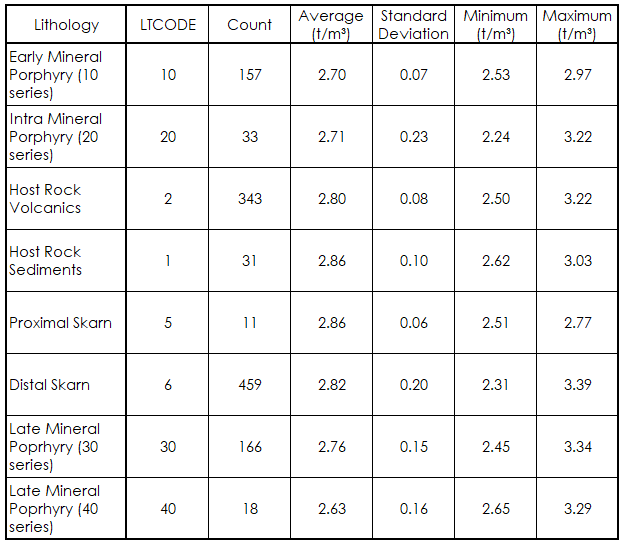

Bulk density |

|

Three methods of bulk density measurements are used:

All methods are deemed appropriate for use in the Cortadera Resource. Density values for fresh rock (below the ‘top of fresh rock’ surface) are calculated by lithology and then assigned to the final model based on the coded lithology.

No density measurements have been taken in the oxide or transitional zones. For the purposes of this resource model, transitional material has been coded as 90% of the fresh density and oxide material has been coded as 80% of the fresh density. A programme to collect densities in the weathered material has commenced and results will be included in the next mineral resource update. |

||||||||||||||||||||||||

|

Classification |

|

Classification wireframes were constructed to define the limits of Indicated and Inferred material. These took account of geological and grade continuity between drillholes, number of samples informing the estimate, quality of the estimate (slope of regression, kriging efficiency and search pass block is filled on) and confidence in the estimate (with a conservative approach taken where the use of soft-domain boundary conditions were coupled with sparse data density). The Competent Person has assessed the drillhole database validation work and QAQC undertaken by HCH and was satisfied that the input data could be relied upon for the estimation of Indicated and Inferred Mineral Resources. The Mineral Resources have been classified based on confidence in geological and grade continuity and taking into account data quality (including sampling methods), data density and confidence in the block grade estimation. The classification applied appropriately reflects the Competent Person’s view of the mineralisation. |

||||||||||||||||||||||||

|

The mineral resource estimate was developed independently and reviewed internally by HCH. |

|||||||||||||||||||||||||

|

Discussion of relative accuracy/confidence |

|

The estimate has been classified according to the relative accuracy and confidence that the Competent Person has in the reported global Indicated and Inferred Mineral Resource. In the Competent Person’s opinion, alternative interpretations would have a minor effect on the reported Indicated material globally and possibly a minor to moderate effect on the Inferred material globally, however this is not considered to impact the overall project technical and economic evaluation. This discussion is qualitative only as no quantitative assessment of confidence has been completed. Production data is not yet available to enable a comparison. |

||||||||||||||||||||||||

JORC Code Table 1 for Productora

The following table provides a summary of important assessment and reporting criteria used for the reporting of Mineral Resource and Ore Reserves in accordance with the Table 1 checklist in the Australasian Code for the Reporting of Exploration Results, Minerals Resources and Ore Reserves (The JORC Code, 2012 Edition).

The Productora MRE will be reported to the standard of the Canadian National Instrument 43-101 “Standards of Disclosure for Mineral Projects”, and as such has been completed by a Qualified Person (QP). A QP under NI43-101 guidelines is interchangeable with a Competent Person (CP) under the JORC Code and has been referred to as such below.

The follow list provides the names and the sections for Competent Person responsibilities:

Section 1, 2 and 3: C. Easterday – MAIG (Hot Chili Limited), E. Haren (MAusIMM and MAIG) (Haren Consulting Pty Ltd)

Section 1 Sampling Techniques and Data

|

Criteria |

JORC Code explanation |

Commentary |

|

Sampling techniques |

|

Reverse circulation drilling (RC) was used to drill 1 metre intervals to produce a 1m bulk sample and representative 1m split samples (12.5%, or nominally 3.5kg) were collected using a cone splitter. Geological logging was completed and mineralised intervals were determined by the geologists to be submitted as 1m split samples. In logged unmineralised zones 4m composite scoop samples were submitted to the laboratory for analysis. If these 4m composite samples came back with Cu grade > 0.2% the corresponding original 1m split samples were submitted to the laboratory for analysis. Diamond drilling (DD) was used to produce drill core with a 63.5mm (HQ) diameter. At the Productora deposit, diamond core was routinely whole core sampled on 1m intervals. At Alice, diamond core has half core sampled. Sampling techniques used are deemed appropriate for the style of copper-gold-molybdenum mineralisation and deposit type. |

|

Drilling techniques |

|

Reverse Circulation drilling used 143 to 130mm diameter drill bits. RC drilling employed face sampling bits ensuring contamination during sample extraction is minimised. Diamond drilling used HQ drill bits (96mm external and 63.5mm internal diameter). Diamond drilling was double tube. Diamond core was oriented using the Reflex ACT III core orientation tool. Diamond tails were drilled to test depth extensions of the mineralisation below depths which RC drilling could not penetrate. Diamond tails were completed on RC pre-collars, and not cored from surface. |

|

Drill sample recovery |

|

Drilling techniques to ensure adequate RC sample recovery and quality included the use of “booster” air pressure. Air pressure used for RC drilling was 700-800psi. Logging of all samples followed established company procedures which included recording of qualitative fields to allow discernment of sample reliability. This included (but was not limited to) recording: sample condition (wet, dry, moist), sample recovery (poor, moderate, good), sample method (RC: scoop, cone; DD core: half, quarter, whole). Overall logging of RC and diamond sample recovery for the Productora deposit; 95.1% of samples as “good”, 2.8% “moderate” and 2.1% as “poor” or not recorded. Logged recovery for the Alice deposit; 99.7% as “good”. RC samples weights were recorded by ALS upon sample receipt for assay. At the Productora deposit, a comparison between wet and dry, and moist and dry samples was undertaken to define confidence in sampling wet and to assist potential domain decisions. This comparison has highlighted some uncertainty that could relate to either natural mineral zonation within the shatter complex with elevation, or alternatively could relate to bias in wet or moist RC sampling. Future work will continue to address this uncertainty. Sample weights were routinely measured by ALS laboratory. An analysis of these weights and their corresponding grades did not identify any bias concern. At Productora there are quite a few RC intervals twinned with diamond holes. A direct comparison between nominally equivalent intervals shows there is some short-scale structural and mineralisation noise in all elements. Population comparison plots for matched twins was attempted but were not informative. A qualitative validation of mineralisation domains suggest that there is acceptable correlation with no discernible bias in the twinned mineralisation intervals and assay ranges. |

|

Logging |

|

Geological logging of samples followed established company and industry common procedures. Qualitative logging of samples included (but was not limited to) lithology, mineralogy, alteration, veining and weathering. Diamond core logging included additional fields such as structure and geotechnical parameters. Photography of diamond core was routinely completed and is stored on the company’s data server. A cumulative total of 245,327m of drilling has been undertaken and utilised in the estimation of the Productora deposit. This includes 212,327m of RC (208,135m by HCH, 4,557m pre-HCH) and 32,636m of DD (all by HCH). A cumulative total of 9,593m of drilling has been undertaken and utilised in the estimation of the Alice deposit. This includes 9,005m of RC and 588m of DD Every metre (100%) of HCH drilling was geologically logged. Litho-geochemical logging was undertaken using the assay results from the Me-ICP61 technique (33 elements). Alteration geochemistry characterization was also completed using ME-ICP61 assay data. |

|

Sub-sampling techniques and sample preparation |

|

Entire whole HQ diamond core was sampled at the Productora deposit. Half core HQ diamond core was sampled at the Alice deposit. Splitting of RC samples occurred via a cone splitter by the RC drill rig operators. Cone splitting of RC drill samples occurred regardless of the sample condition (wet, moist, or dry). All resource and exploration samples were submitted to ALS La Serena Coquimbo (Chile) for sample preparation before being transferred to ALS Lima (Peru) for multi-element analysis. The sample preparation included:

Sample length, weight and collection methods of RC samples are considered acceptable for estimation of this style of copper-gold-molybdenum mineralisation which is characterised by variably fine to medium grained, disseminated to locally blebby chalcopyrite mineralisation. |

|

Quality of assay data and laboratory tests |

|

All resource and exploration samples (RC chips and DD core) were assayed by industry standard methods through commercial laboratories in Chile (ALS La Serena Coquimbo) and Peru (ALS Lima):

Hot Chili utilised several multi-element pulp “mineralised standards” (certified reference material; “CRM”) and one certified reference analytical (pulp) “blank”, all supplied by Ore Research & Exploration Pty Ltd. One “mineralised standard” was chosen at random and inserted every 50th metre into each batch of samples submitted for analysis. One certified “blank” sample was also inserted every 100th sample. The material types and grade ranges for the CRMs correspond to the rock types and mineralisation grades routinely encountered within the drilling on the Productora project. QA/QC samples and their Insertion Rates (IR), as a percentage of the 174,476 samples from all HC Productora project drilling to date are:

Routine Field Duplicates for RC samples were submitted at a rate of 1 in every 50 samples. Diamond core was whole sampled hence field duplicate samples were not able to be taken. However a split sample duplicate was taken after the initial crush stage at the laboratory, whereby the crushed sample was split in half, with one half retained as the primary sample and the second half being used a duplicate sample. This type of duplicate sample cannot test the precision of the primary sampling technique, however it can test the precision of all steps at the laboratory thereafter. Results from CRM (standards, blanks) and the duplicates gives confidence that acceptable relative levels of accuracy and precision of assay data returned for ALS have been obtained. The analytical laboratory (ALS) also provided their own routine quality controls within their own practices. The results from their own validations were provided to Hot Chili Ltd. Future studies will assess the insertion (and rate) of additional pulp and or coarse standards or blanks in future drilling programmes. |

|

Verification of sampling and assaying |

|

There have been two separate periods of independent sampling at the Productora project. In November 2012 a total of 17 samples, from 4 drillholes selected at random, were taken by Coffey Mining personal during a site visit. In October 2014, Coffey Mining personal were again undertaken an independent site visit and collected a total of 60 samples from approximately 18 drillholes, with samples collected for various locations, styles and levels of mineralisation. In each case, samples were taken by the independent auditor and delivered in person to the ALS laboratory in Coquimbo (Chile). The results were directly sent to independent auditor in Perth (Australia) and supported the original assays. A full pulp and coarse reject sample library is located at the Productora site, these samples are available for verification sampling if required. 236 samples, representing 1% of the most recent drilling programme, had pulp and coarse rejects submitted to an alternative commercial laboratory (Bureau Veritas) for Umpire checks and validation against the primary laboratory. These samples, along with those tested during previous drilling programmes, show an acceptable relative correlation with primary laboratory (ALS) results. At the Productora deposit there are quite a few RC intervals twinned with diamond holes (and two at Alice). A direct verification comparison between nominally equivalent intervals shows there is some short-scale structural and mineralisation noise in all elements. Population comparison plots for matched twins was attempted but were not informative. This does make quantitative correlation troublesome, but visual validation of mineralisation domains suggest that there is acceptable correlation, and no apparent bias in the twinned mineralisation intervals and assay ranges. Hot Chili has strict procedures for data capture, flow and data storage, and validation. Limited adjustments were made to returned assay data for the resource estimate; values that returned lower than detection level were set to the methodology’s detection level and copper values were converted from ppm to %. Various analytical techniques have been used for analysis of ore grade elements (including Au and Cu). Therefore, a ranking has been applied to these elements ensuring the highest priority assay result is used for resource estimation. All assay values (from all analytical techniques) are stored in the database for completeness. Order of ranking for copper assays: ME-MS61 then ME-ICP61. |

|

Location of data points |

|

Drill collars were surveyed by contract surveying company Geotopo Exploraciones Limited using a Topcon HiPer GPS, using dual frequency, Real Time, with +/- 0.1cm accuracy (N, E and RL). Downhole surveys using a gyroscopic instrument were completed by contract downhole surveying company’s Wellfield and North Tracer. All Hot Chili holes at Productora have gyroscopic DH survey measurements commencing at the start of hole with readings taken every 10th metre until end of hole. Gyroscopic surveys are an accurate form of downhole survey as there is no risk of magnetic interference to the measured survey reading. The WGS84 UTM Zone 19S coordinate system was used for all Hot Chili undertakings. A detailed topographic survey was supplied by Geoimage from satellite data corrected by regional STRM points. This provided spot heights at 50cm spacing across the entire project area. Several subsampling steps were undertaken to balance file size vs. local accuracy with a final 20m x 20m grid was chosen as providing a management file size while still honouring and reproducing known local data points. The detail of topography is adequate for modelling and resource estimation purposes. |

|

Data spacing and distribution |

|

Drillhole spacing at the Productora deposit is on a nominal 80m by 40m grid (40m between drilling on east-west sections and 80m north or south between sections). For Alice deposit, while the resource was drilled by a variety of drilling angled, the drilling provided a nominal 80m by 50m. This drillhole spacing has provided a sufficient level of support for geological and mineralisation modelling. Geological and grade continuity is sufficient for mineral resource estimation, with both Indicated and Inferred resources being classified at Productora. In unmineralised areas, 4 metre composite samples were taken from the RC drill holes. These 4m composite samples represent 8% for Productora deposit, and 6.6% for the Alice deposit, of all assay sample data used in resource estimation. The 1m samples comprise 91.9% and 93.3% for Productora and Alice respectively. Within higher grade mineralised areas 1m samples comprise >98% of all samples used in estimation for both Productora and Alice deposits. |

|

Orientation of data in relation to geological structure |

|

The majority of Productora drilling has been oriented approximately perpendicular to the overall NNE structural trend of the Productora project area, with drillholes angled at -60° to -90° towards the east or west to optimize drill intersections of the moderate to steeply dipping mineralisation. A list of drillholes and orientations is appended in Explanatory Notes below. Considering the type of deposit and style of mineralisation, the drilling orientation and subsequent sampling is considered to be unbiased in its representation of reported material for estimation purposes. |

|

Sample security |

|

Hot Chili has strict chain of custody procedures that are adhered to for drill samples. All samples for each batch have the sample submission number/ticket inserted into each bulk polyweave sample bag with the id number clearly visible. The sample bag is stapled together such that no sample material can spill out and no one can tamper with the sample once it leaves Hot Chili’s custody. |

|

Audits or reviews |

|

AMC Consultants have reviewed similar procedures for data collection methods used by Hot Chili at the Productora project. In October 2014, an independent consultant from Coffey Mining (now employed by AMC Consultants) was engaged on a fee basis to conduct a site visit to review site practices, QA/QC methods, data capture, site sample processing, laboratory sample preparation, and to undertake a limited amount of independent check samples for comparison with Hot Chili sample results. This review found Hot Chili practices acceptable but with areas of potential improvement. The review also determined the outcome of the check samples had very good results and repeatability noted. |

Section 2 Reporting of Exploration Results

|

Criteria |

JORC Code explanation |

Commentary |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Mineral tenement and land tenure status |

|

The Productora project comprises the following tenements (patentes):

There is only one lease within the Productora project which is subject to a royalty payment. This is the URANIO 1/70 lease, and the royalty is with CCHEN. The details are as follows: 1. After the first 5 years of the lease agreement or upon beginning of the exploitation phase if this situation happens before, the following minimum Net Smelter Royalty (NSR) shall be charged: a). 2% over all metals different from gold. b). 4% over gold. c). 5% over non-metallic products. 2. All of the above are calculated over effective mineral products sold. 3. Every 5 years the parties may re-negotiate the value of the NSR up or down to 50% of their value. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Exploration done by other parties |

|

In the 1980’s Comisión Chilena de Energia Nuclear (CCHEN) undertook exploration near and to the south of the Productora mines for uranium. At least 10 shallow RC holes were completed. Additional work in the area included; mapping, surface geochemical sampling, ground spectrometry, magnetometry and trenching. In ~1997 General Minerals Corporation (GMC) drilled 8 RC holes. In ~1999 General Minerals Corporation (GMC) and Teck Corporation drilled eleven RC holes targeting secondary copper enrichment zones in the southern portions of the central lease. Additional work included IP survey. In 2000 as MSc. Thesis was completed by Ms K.A Fox (Colorado School of Mines). This thesis is titled “Fe-oxide (Cu-U-Au-REE) Mineralization and Alteration at the Productora Prospect”. There are two underground copper mines within the central lease (Productora 1/16). Underground mining ceased in 2013 under agreement with Hot Chili, and has recently recommenced in July 2020. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Geology |

|

The majority of the mineralisation at the Productora Project is in the Productora copper-gold-molybdenum deposit, which is a structurally focused tourmaline breccia. This is located in the Neocomian (lower Cretaceous) Bandurrias Group, a thick volcano-sedimentary sequence comprising intermediate to felsic volcanic rocks and intercalated sedimentary rocks. Dioritic dykes intrude the volcano-sedimentary sequence at Productora, typically along west- to northwest-trending late faults, and probably represent sub-volcanic feeders to an overlying andesitic sequence not represented in the resource area. The host sequence dips gently (15-30°) west to west-northwest and is transected by several major north- to northeast-trending faults zones, including the Productora fault zone which coincides with the main mineralised trend. These major fault zones are associated with extensive tectonic breccia (damage zones) that host copper-gold-molybdenum mineralisation. Later faults cross-cut and offset the volcano-sedimentary sequence together with the Productora (and sub-parallel) major faults. Late faults generally show a west to north-westerly strike and while generally narrow, are locally up to 20m wide. The volcano-sedimentary sequence at Productora is extensively altered, particularly along major faults and associated damage zones, and a distinctive alteration zonation is evident. The distribution of alteration mineral assemblages and spatial zonation suggest a gentle northerly plunge for the Productora mineral system, disrupted locally via vertical and strike-slip movements across late faults. The Alice copper-gold-molybdenum deposit is a mineralised porphyry hosted in the same broad lithological sequence as the Productora deposit. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Drillhole Information |

|

Significant intercepts at the Productora project have been released periodically to the Australian Stock Exchange, and are available in public statement / press releases at either www.hotchili.net.au or www.asx.com.au (company code = HCH) . |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Data aggregation methods |

|

No new exploration results are being reported for the Mineral Resource area. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Relationship between mineralisation widths and intercept lengths |

|

The majority of drilling at the Productora Project is oriented -60 to -80° toward 090°azimuth, but there were numerous scissor drill holes which are oriented at -60 to -80° degrees towards an azimuth of 270° to ensure geological representivity and to also preferentially target east dipping mineralisation. Drilling off section or plunging in or out of sections was required on an ad hoc basis due to limitations on drill position availability or to preferentially test specific structural orientations. Mineralisation in the Productora deposit comprises two contrasting styles. The predominant style is characterised by narrow, N to NE trending tourmaline-cemented breccia bodies. Sub-vertical feeder stocks, of 2-5m width at depth, increase with elevation, to wider high-grade mineralisation zones. These wider brecciated zones vary in orientation with central lodes tending to be sub-vertical with an upper flex in wider mineralised zones to dip approximately 70° towards the west, also flanking shallower eastern and western lodes dip moderately west and east respectively. There are also some locally steeply east dipping lodes. In likely structurally conducive dilation zones, these discrete breccia zones hydraulically propagate outward and can commonly coalesce to become larger zones of hydrothermal damage. These larger damage zones are most probably defined by a combination of structural and intra-lithological controls. Drilling at deeper levels at Productora has demonstrated thinning breccia lodes, with some ductile features, that continue to a greater depth. The Alice mineralisation has a single porphyry body in close proximity to a lithocap. Within the mineralisation, there appears to be a distinct difference between chalcopyrite-dominant and pyrite-dominant areas. Zones within the chalcopyrite dominant domains (i.e. low pyrite: chalcopyrite ratio) correlate with intense A-veins and B-veins, and also higher copper grades. Copper mineralisation appears both within veining and disseminated within the groundmass proximal to veining. Late albite (+/- epidote +/-sericite) appears to have overprinted / removed chalcopyrite (Cu, S). Considering the types of deposit and style of mineralisation, the drilling orientation and subsequent sampling is considered to be unbiased in its representation of reported material for estimation purposes. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Diagrams |

|

Diagrams of the Productora and Alice resource estimates are shown in the attached announcement, including an oblique section of the model within the 2016 PFS Design pit shape, and cross sections at two locations; Habanero and CCHEN. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Balanced reporting |

|

No new exploration results are being reported for the Mineral Resource Area. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Other substantive exploration data |

|

Other exploration data available:

Multi element ME-MS61 (48 element) analysis was completed on surface soil samples, rock chips and selected downhole samples over several HCH exploration and drilling campaigns. This data was used for 3D geochemical modelling completed independently by Fathom Geophysics in 2021 following the geochemical element zoning models for the Yerington porphyry copper deposit in Nevada (Cohen, 2011]; and Halley et al., 2015) Cohen, J.F., 2011, Mineralogy and geochemistry of alteration at the Ann-Mason copper deposit, Nevada: Comparison of large-scale ore exploration techniques to mineral chemistry: M.Sc. thesis, Corvallis, Oregon, Oregon State University, 112 p. plus appendices. Halley, S., Dilles, J.H, and Tosdal, R.M., 2015, Footprints: Hydrothermal alteration and geochemical dispersion around porphyry copper deposits, Society of Economic Geologists Newsletter v. 100, p 1, 12-17. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Further work |

|

Infill, extensional and near-mine mine exploration drilling is planned for the Productora Project. Exploration drilling of the Fathom Geophysics 3D geochemical targets are underway and are not included in the resource model. Dedicated studies are required to test the reliability and representivity of RC samples, where the relationship of wet or deeper RC samples on Cu-Au-Mo grade needs to be defined. Dedicated studies are required to further assess potential sub-domains of the oxide and transitional domains in reference to spatial variations in potential recoverable resources. |

Section 3 Estimation and Reporting of Mineral Resources

|

Criteria |

JORC Code explanation |

Commentary |

|||||||||||||||||||

|

Database integrity |

|